Ukuvula icandelo lomgqomo womatshini

Olunye uyilo lomphanda lubonelela ngolungelelwaniso olulodwa lwe-twin screw extruders.Xa sidibanisa umphanda ngamnye ngolungelelwaniso olufanelekileyo lwesijirufu, siya kuqhuba uphononongo olubanzi nolunzulu ngakumbi lwezi ntlobo zombhobho ngamnye weyunithi yokusebenza ngokuthe ngqo kuloo ndawo ye-extruder.

Icandelo ngalinye lombhobho lineshaneli enemilo ezi-8 apho i-screw shaft idlula khona.Umgqomo ovulekileyo uneendlela zangaphandle zokuvumela ukutya okanye ukukhupha izinto eziguqukayo.Olu luyilo lwemibhobho evulekileyo lungasetyenziselwa ukondla kunye nokukhupha, kwaye lunokubekwa naphi na kuyo yonke indibaniselwano yomphanda.

Ukutya

Ngokucacileyo, izinto kufuneka zondliwe kwi-extruder ukuqala ukuxuba.Umgqomo wokutyisa ngumphanda ovulekileyo owenzelwe ukuba ube nokuvuleka phezulu kombhobho apho izinto zityiswa khona.Eyona ndawo ixhaphakileyo yedrum yokutya ikwindawo yoku-1, engumphanda wokuqala kwicandelo lenkqubo.Izinto ze-granular kunye namasuntswana ahamba ngokukhululekileyo alinganiswa ngokusebenzisa i-feeder, evumela ukuba bawele ngokuthe ngqo kwi-extruder ngokusebenzisa i-barrel yokutya kwaye bafikelele kwi-screw.

Iipowda ezinoxinano oluphantsi lokupakisha zihlala zibanga imingeni njengoko umoya uhlala uphethe umgubo owayo.Lo moya ubalekayo uthintela ukuhamba komgubo okhanyayo, unciphisa amandla omgubo wokutya ngesantya esifunekayo.

Enye inketho yokondla umgubo kukuseta imibhobho emibini evulekileyo kwimibhobho emibini yokuqala ye-extruder.Kulo cwangciso, i-powder ifakwe kwi-barrel 2, ivumela umoya odibeneyo ukuba ukhululwe kwi-barrel 1. Olu lungelelwaniso lubizwa ngokuba yi-rear exhaust device.I-vent yangasemva ibonelela ngomjelo wokukhupha umoya kwi-extruder ngaphandle kokuthintela i-chute yokutya.Ngokukhutshwa komoya, ipowder inokondliwa ngokufanelekileyo.

Emva kokuba i-polymer kunye nezongezo zondliwa kwi-extruder, ezi ziqina zithunyelwa kwindawo yokunyibilika, apho i-polymer inyibilika kwaye ixutywe kunye nezongezo.Izongezo nazo zinokutyiswa emazantsi omlambo wendawo yokunyibilika kusetyenziswa izixhasi ezisecaleni.

Ukukhupha

Icandelo letyhubhu evulekileyo lingasetyenziselwa ukukhupha;Umphunga oguqukayo owenziwe ngexesha lenkqubo yokuxuba kufuneka ukhutshwe ngaphambi kokuba i-polymer idlule kwi-die.

Eyona ndawo icacileyo ye-vacuum port ibheke ekupheleni kwe-extruder.Eli zibuko lokukhupha lihlala liqhagamshelwe kwimpompo yokucoca ukuqinisekisa ukuba zonke izinto eziguquguqukayo ezithwelwe kwi-polymer melt ziyasuswa ngaphambi kokuba zidlule kwintloko yokubumba.I-steam eseleyo okanye igesi kwi-melt ingakhokelela kumgangatho ophantsi we-particle, kubandakanywa i-foaming kunye nokunciphisa ukuxinana kokupakisha, okunokuthi kuthintele umphumo wokupakisha amaqhekeza.

Icandelo lemiphanda elivaliweyo

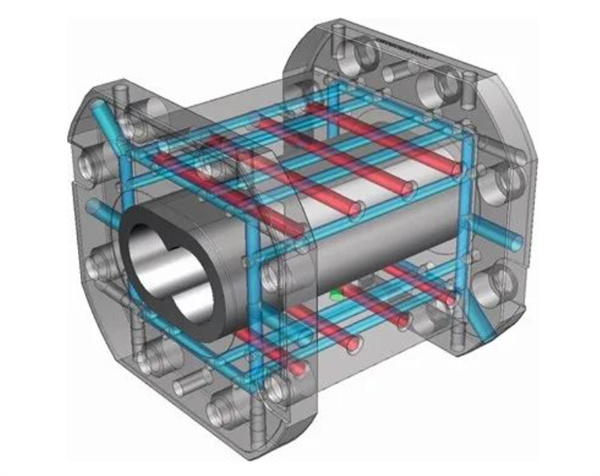

Uyilo oluqhelekileyo lwe-cross-sectional ye-barrel ngokuqinisekileyo ngumbhobho ovaliweyo.Inxalenye yomgqomo isonga ngokupheleleyo i-polymer inyibilika kumacala omane e-extruder, kunye nokuvulwa okunemilo emi-8 kuphela evumela umbindi wesikrufu ukuba udlule.

Emva kokuba i-polymer kunye naziphi na ezinye izongezo zondliwe ngokupheleleyo kwi-extruder, izinto ziya kudlula kwicandelo lokuhambisa, i-polymer iya kunyibilika, kwaye zonke izongezo kunye neepolymers ziya kuxutywa.Umgqomo ovaliweyo ubonelela ngolawulo lobushushu kuwo onke macala e-extruder, ngelixa umgqomo ovulekileyo unezifudumezi ezimbalwa kunye nemijelo yokupholisa.

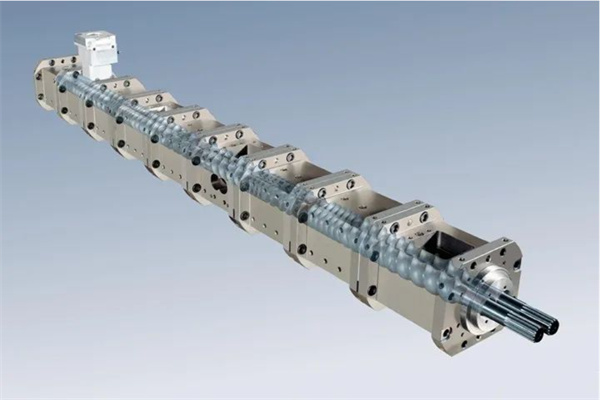

Ukudibanisa umgqomo we-extruder

Ngokuqhelekileyo, i-extruder iya kuhlanganiswa ngumenzi, kunye nesakhiwo se-barrel esihambelana nokucwangciswa kwenkqubo efunekayo.Kwiinkqubo ezininzi zokuxuba, i-extruder inombhobho wokutya ovulekileyo kwi-barrel yokutya 1. Emva kweli candelo lokutya, kukho imibhobho emininzi evaliweyo esetyenziselwa ukuthutha izinto eziqinileyo, i-polymers ezinyibilikayo, kunye nokuxuba iipolymers ezinyibilikisiweyo kunye nezongezo kunye.

I-cylinder yokudibanisa inokufumaneka kwi-cylinder 4 okanye i-5 ukuvumela ukondla kwe-lateral of additives, ilandelwa ngamasilinda amaninzi avaliweyo ukuqhubeka nokuxuba.I-vacuum exhaust port ifumaneka kufuphi nesiphelo se-extruder, ilandelwa ngokusondeleyo ngumbhobho wokugqibela ovaliweyo phambi kwentloko yokufa.Umzekelo wokudibanisa umgqomo unokubonwa kwi-Figure 3.

Ubude be-extruder budla ngokubonakaliswa njengomlinganiselo wobude ukuya kwi-screw diameter (L/D).Ngale ndlela, ukwandiswa kwecandelo lenkqubo kuya kuba lula, njengoko i-extruder encinci ene-L / D ratio ye-40: 1 inokwandiswa kwi-extruder enobubanzi obukhulu kunye nobude be-L / D be-40: 1.

Ixesha lokuposa: Apr-04-2023