I-LB-WaterRing Cutting Granulating Line

| Umzekelo | LBWR-80 | LBWR-100 | LBWR-140 | LBWR-160 | LBWR-180 |

| Screw Model | 80/38:1 | 100/38:1 | 140/38:1 | 160/38:1 | 180/38:1 |

| Ugqithiso(kg) | 120-160 | 260-400 | 450-600 | 600-800 | 800-1000 |

| Amandla eMoto(kW) | 55 | 110 | 200 | 250 | 315 |

I-Automatic Conveyor

Umqhubi we-AC olawulwa yi-motor eqhutywayo

Isikhangeli sesinyithi njengokhetho lokulawula isenzo somhambisi ngesilumkiso kunye nokumisa.

I-conveyor yokutya elawulwa yi-AC Driver yokondla isantya ixhomekeke kumthamo wexesha langempela le-compactor.

Yakha-ngaphakathi iCompactor

I-Stator kunye ne-rotor ukusika izinto eziluhlaza. Ukukhuhlana kwezinto ezilahlwayo kwandisa ubushushu kwi-compactor. Ubushushu obuphezulu bunceda izinto eziphathekayo ngokunciphisa umswakama kunye nokuhlukana kothuli kwizinto ezilahlayo. Isixhobo se-Degassing sivumela umswakama ukuba uphume kwi-compactor kwaye unikeze izinto eziphathekayo ngemeko engcono yokuqhubela phambili

Isikrufu esinye I-Extruder

Isicelo singqinelanise isikrufu kunye nemoto kwimveliso ezinzileyo kunye nexesha elide lenkonzo. Umgangatho ophezulu wezinto zokujija kunye nokusetyenzwa kwe-Bi-metal kwi-extrusion ephezulu esebenzayo kunye nexesha elide lokusebenza.

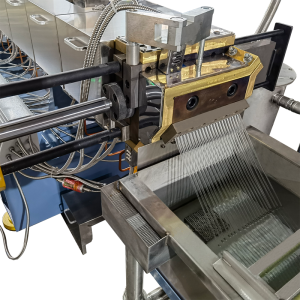

Hydraulic Melt filter Mold

304 Izikrini zentsimbi ezinobungakanani obulungiselelwe umnatha

Ipleyiti yeHydraulic okanye umzimba wokucoca isilinda okhoyo.

Isifudumezi seBronze sokufudumala okuphezulu

Inkqubo yokutshintsha isikrini esizenzekelayo ngokukhetha

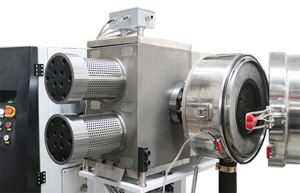

Amanzi-Ring Granulator

Uxinzelelo loqhagamshelwano phakathi kwemela ejikelezayo kunye nobuso bokufa bujongwa ixesha elide lokusika kunye nomgangatho ophezulu weegranules. Isantya sokujikeleza somese sisekelwe kuxinzelelo olunyibilikayo kwaye luhlengahlengiswe ngokuzenzekelayo. Isixhobo somese esijikelezayo silungelelaniswa ukugcinwa. Ukutshintshwa kweemela ngokulula konga ixesha ngolondolozo.

I-Vibration Sieve

ImiSebenzi emibini, ukuNciphisa amanzi kunye noLawulo loBubungakanani, kwiSieve yeVibration:

Emva kwe-water-ring granulating iigranules zihanjiswa emanzini. KwiVibration Sieve amanzi ayabaleka kwaye iigranules zihlala kwelinye inyathelo.

Ubungakanani beegranule ezilawulwa sisihluzo sokungcangcazela esincinci kakhulu okanye iigranule ezinkulu kakhulu ziya kuphaphazelwa ngaphandle. Iigranules kuphela, ezihambelana nemfuno yobukhulu ziya kuhanjiswa kwi-silo yokugcina ngomoya.

Ukomisa inkqubo

Ukomisa i-granules, i-centrifuge-drying kunye ne-air-transporting concept isetyenziswa. IiGranules ziya kuthuthwa ngomoya kwisisele sokugcina kwaye ukufuma kwezinto kuya kuba ngaphantsi kwe-1%.

Ukugcinwa kweSilo

IiGranules zokugqibela ziya kugcinwa kwisisele. Ngokusekwe kwimfuno inkqubo yokubekwa kweliso kwi-intanethi kunye nokulinganisa iya kusetyenziswa.