LB-PP/PE Ngaphantsi kwamanzi Ukusika uMshini wokuNciba iGranulating Line

| Umzekelo | LBUW-40 | LBUW-50 | LBUW-60 | LBUW-70 | LBUW-80 | LBUW-90 |

| Screw Model | 41/24-80:1 | 52/24-80:1 | 62/24-80:1 | 71/24-80:1 | 81/24-80:1 | 93/24-80:1 |

| Ugqithiso(kg) | 130 | 250 | 400 | 500 | 800 | 1000 |

| Amandla eMoto(kW) | 37 | 75 | 110 | 160 | 250 | 315 |

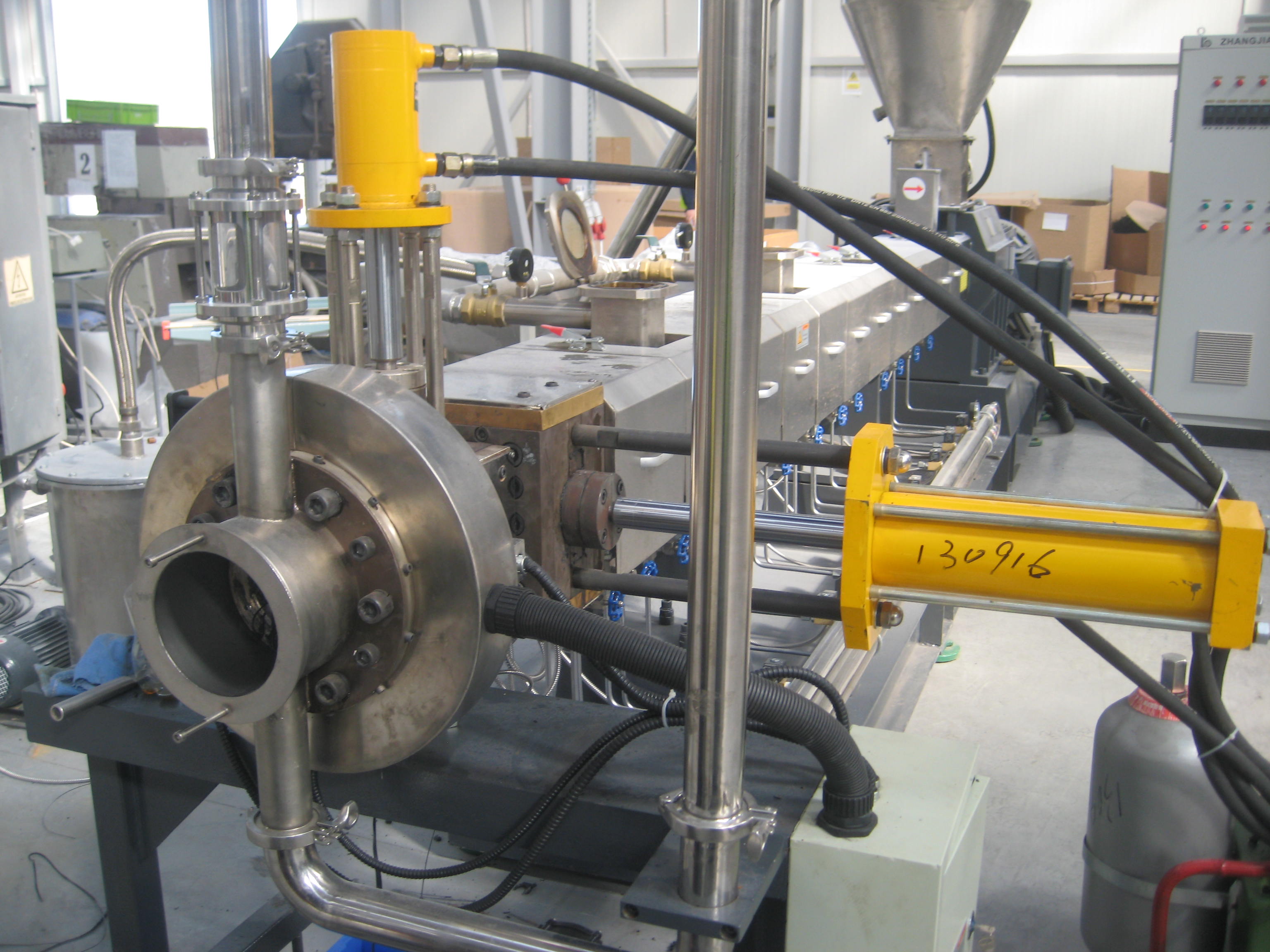

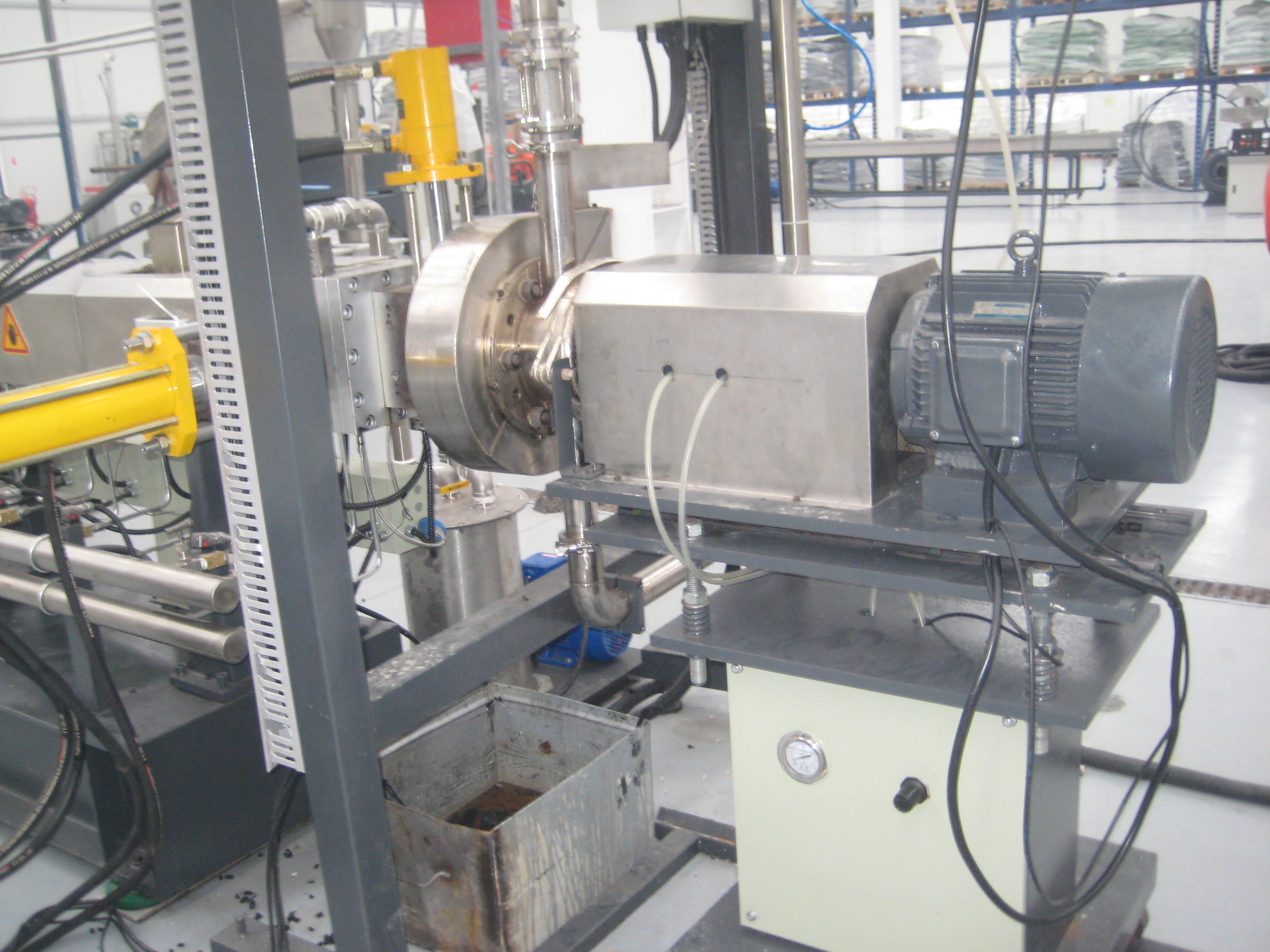

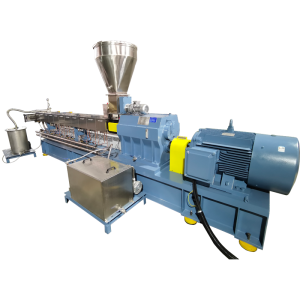

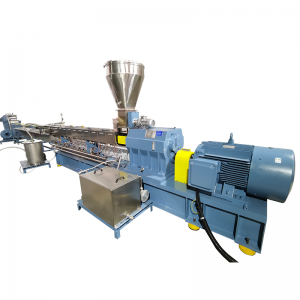

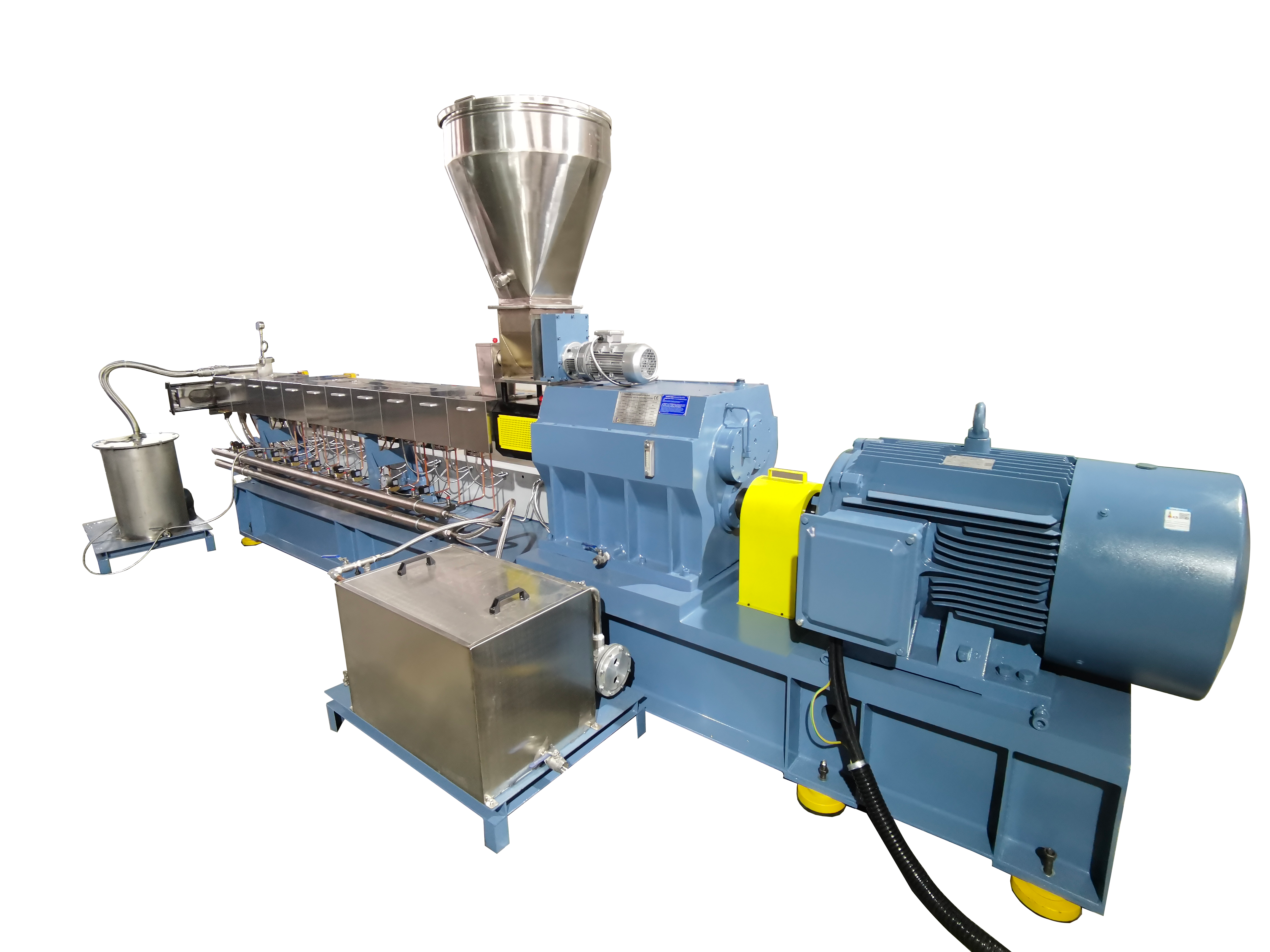

I-Parallel Twin Screw Extruder

Ngokusekelwe kwisicwangciso sokuvelisa esilungiselelweyo sineengcamango ezahlukeneyo ze-extrusion zokuzikhethela. I-Parallel Twin Screw Extruder isekelwe kumava ethu asetyenziswa kakhulu kwisisombululo se-extrusion, esidibanisa nesixhobo esingaphantsi kwamanzi se-granulating.

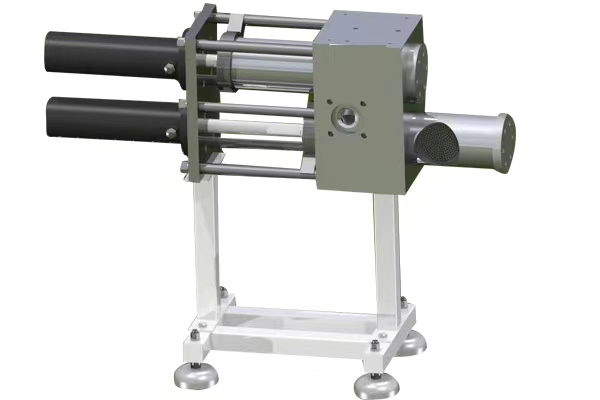

Umtshintshi wesikrini

Ukutshintshwa kwesikrini kusetyenziselwa ukucoca ukungcola kwi-melt (isanti, isinyithi, iiplastiki ezahlukeneyo) ezinciphisa umgangatho wegranule. Kukho uhlobo olwahlukileyo lokutshintsha kwesikrini okufana nesinye- okanye ipleyiti etshintshwayo yesikrini kunye nesinye-okanye esiphindwe kabini sokutshintsha isikrini. Ngokusekwe kwimeko yokusebenza eyahlukileyo, kuya kwamkelwa isitshintshi esifanelekileyo sesikrini.

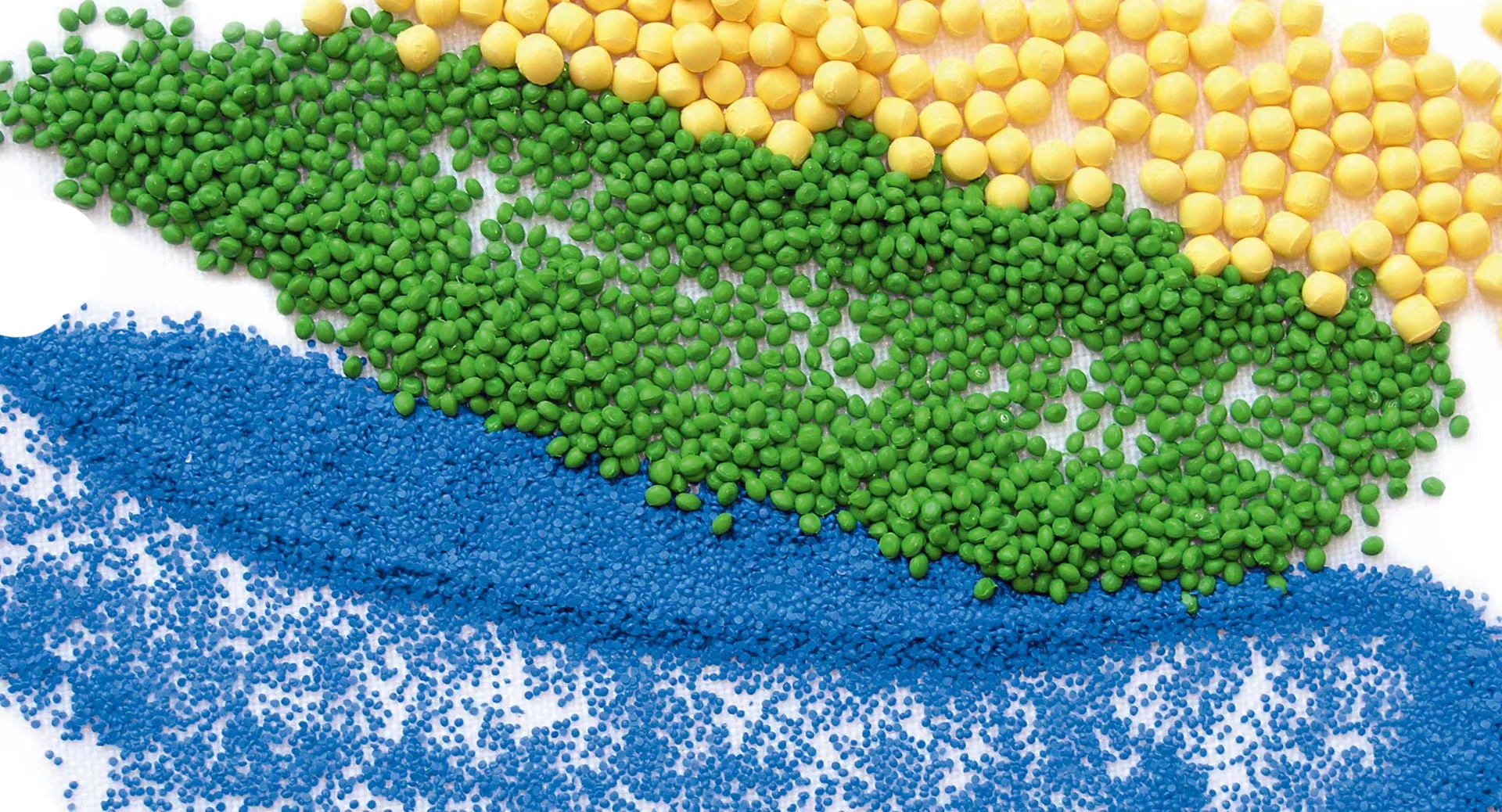

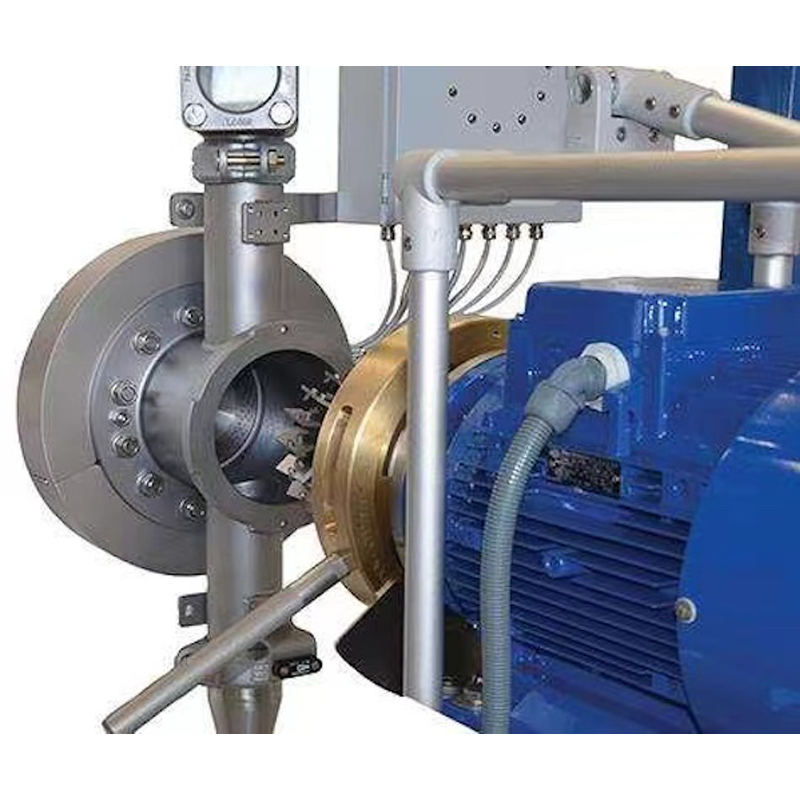

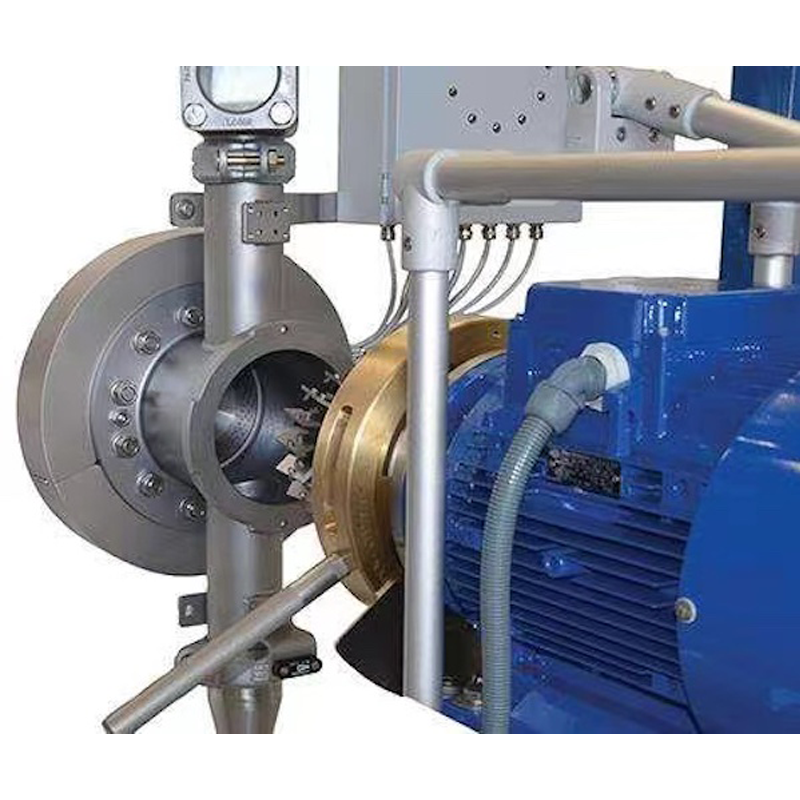

Inkqubo yeGranulating engaphantsi kwamanzi

QhubaUxinzelelo lwesenzo phakathi kwemela ejikelezayo kunye nobuso bokufa bujongwa ixesha elide lokusika kunye nomgangatho ophezulu weegranules. Isantya sokujikeleza somese sisekelwe kuxinzelelo olunyibilikayo kwaye luhlengahlengiswe ngokuzenzekelayo. Isixhobo somese esijikelezayo silungelelaniswa ukugcinwa. Ukutshintshwa kweemela ngokulula konga ixesha ngolondolozo.

Ukukhupha amanzi kwi-Centrifugal

Ikwahlula iigranules kunye namanzi. IiGranules ziya kuthuthwa ngokomiswa kwi-centrifugal ukusuka ezantsi ukuya phezulu kwisixhobo sokukhupha amanzi. Ngexesha lokunyusa umswakama uya kuncitshiswa ngokufanelekileyo.

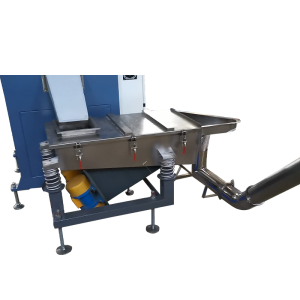

Visisefo se-ibration

TIsisefo sokungcangcazela sihluza iigranules kunye nobukhulu baso. Iigranule ezinkulu kakhulu okanye ezincinci ziya kuhluzwa ngaphandle. Ubungakanani obufanelekileyo kuphela buya kuthuthwa kwi-silo yokugcina.

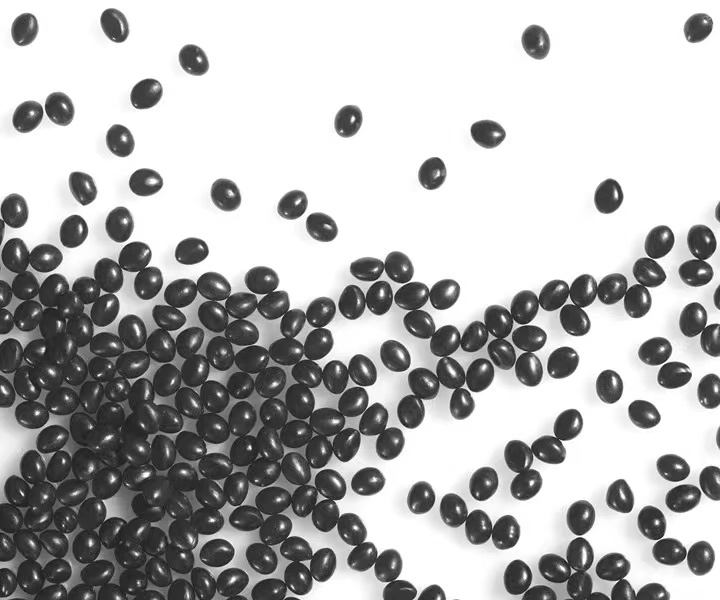

Ukugcinwa kweSilo

IiGranules zokugqibela ziya kugcinwa kwisisele. Ngokusekwe kwimfuno inkqubo yokubekwa kweliso kwi-intanethi kunye nokulinganisa iya kusetyenziswa.