I-LB-PP-R / PE-RT Umgca wokuVelisa uMbhobho

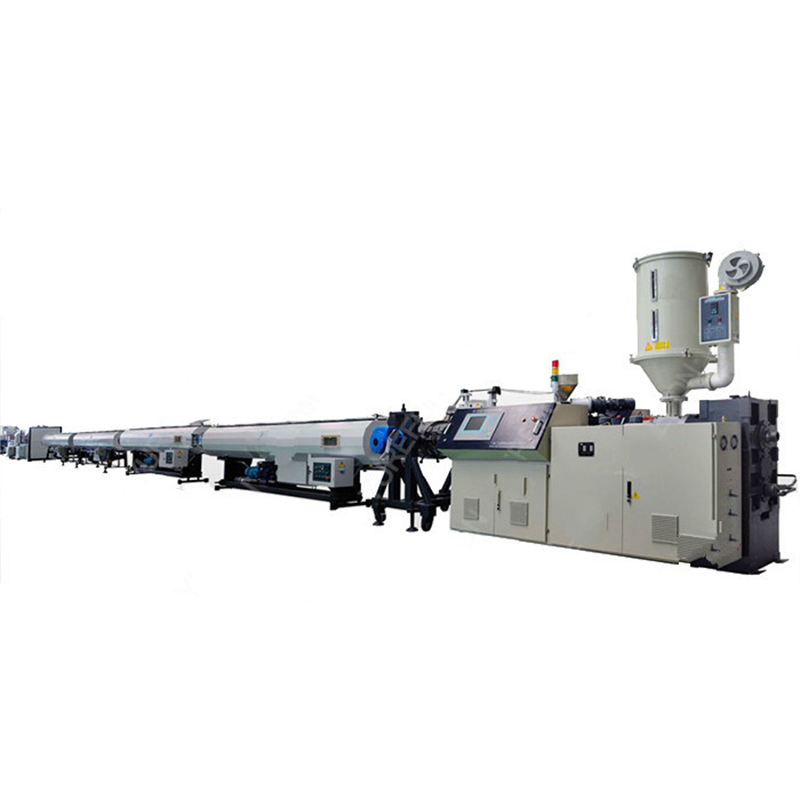

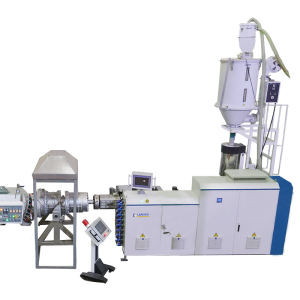

Isixhasi sezinto eziphathekayo—isikruru esinye—isikhunta kunye nekheyibrator—umatshini wokwenza ivacuum—umatshini wokutshiza wokupholisa—umatshini wokukhuthuza—umatshini wokusika ongena-swarfless—stacker.

Isantya esiphezulu sokuvelisa sinokuba yi-35m / min (isiseko kwimibhobho ye-20mm).

Kwiimfuno ezahlukeneyo, umgca wemveliso unokusetyenziselwa ukwenza imibhobho enobubanzi obuhlukeneyo kunye nobukhulu bodonga.

I-extrusion ye-strand ephindwe kabini okanye emine iya kuphucula umthamo wokukhupha umgca we-PP-R weMveliso.

Imveliso ye-PE-RT okanye i-PP-R imibhobho inokuqondwa ngokuguqulwa okufanelekileyo komatshini.

| Umzekelo | Uluhlu lwemibhobho | Screw Model | Amandla emoto | Ubude bubonke | Ubuninzi bemveliso |

| LB-63 | 16-63mm | SJ65 | 37KW | 22m | 80-120kg |

| LB-110 | 20-110mm | SJ75 | 55KW | 30m | 100-160kg |

| LB-160 | 50-160mm | SJ75 | 90KW | 35m | 120-250kg |

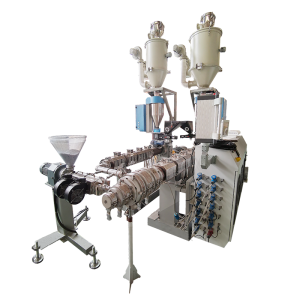

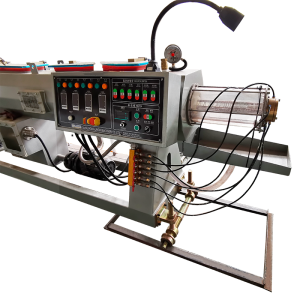

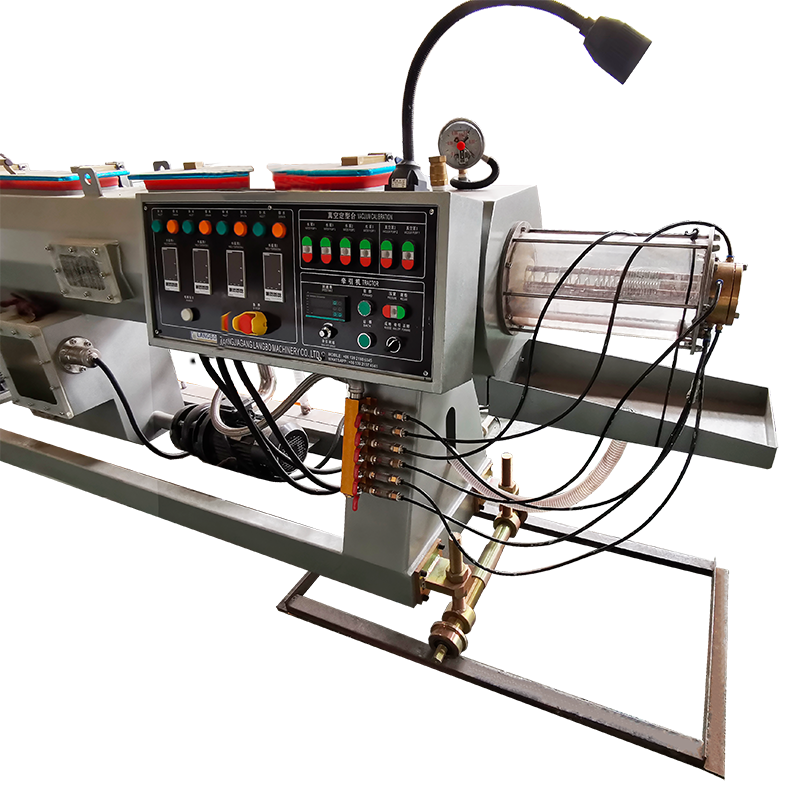

Single screw machine extruder

I-extruder yenziwe ngamacandelo aphezulu e-brand ukuqinisekisa ukuzinza kwemveliso, ukusebenza kakuhle kunye nokuqina komatshini. I-extruder yethu yabela isikrufu somgangatho omnye wamazwe ngamazwe kunye nomphanda. I-screw inobulukhuni obuqinileyo obuqinisekisa ubomi obude benkonzo kunye nefuthe elahlukileyo leplastiki. Lo mbhobho we-extrusion line wamkela amandla asebenzayo e-screw extruder enye enobumba obukhethekileyo, ukusebenza kakuhle kwemveliso kunyuke ngama-30%, ukusetyenziswa kwamandla kungaphantsi kwama-20%.

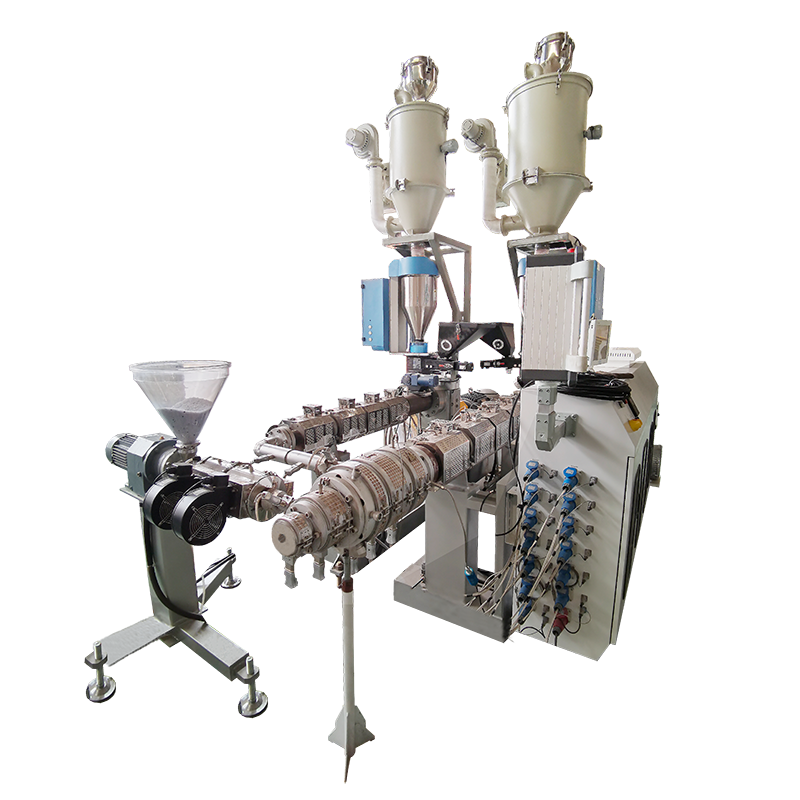

Ukungunda

Umngundo unoyilo lwejelo lokuqukuqela eliphangaleleyo lokuqinisekisa umthamo ophezulu we-extrusion kunye nesiphumo esihle sokunyibilika. Yenziwa kwaye ihlolwe ngumenzi onamava. Ulawulo lobushushu obulungisiweyo kunye noyilo lwejelo lokuhamba luqinisekisa ulawulo oluchanekileyo lobushushu obunyibilikayo.

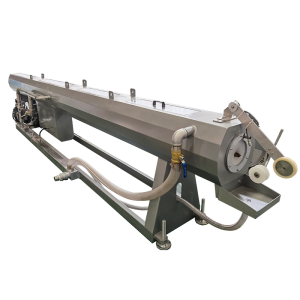

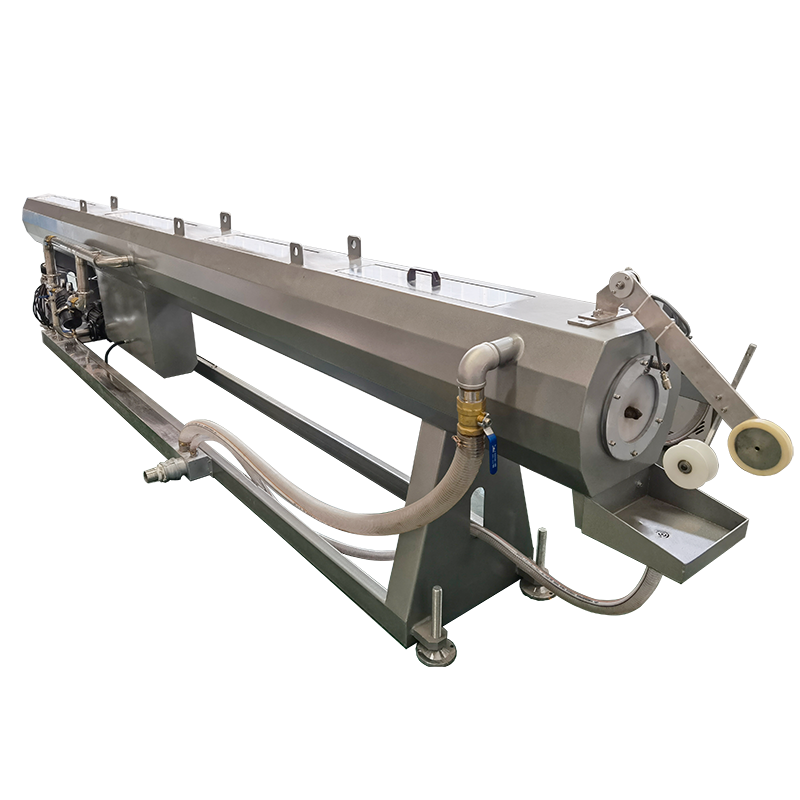

Itanki yokufunxa

Zonke iitanki zethu zokufunxa kunye nokupholisa zenziwe ukusuka kwi-304 yemathiriyeli ye-stainless esemgangathweni ukuthintela ukurusa. Iitanki zethu zokufunxa zilawulwa ngedijithali zivumela inkqubo ezenzekelayo ngokupheleleyo. Umnini kwinqanaba lokuqala letanki yokulinganisa i-vacuum uqinisekisa umbhobho owenziweyo kwaye unika amandla angaphezulu kwimibhobho ehamba phambili.

Itanki yokupholisa

Ubude obaneleyo bokutshiza kunye nokupholisa kuya kuphucula ukusebenza kakuhle kokupholisa. Inkqubo yokulawula ubushushu bamanzi ngokuzenzakalelayo ihlengahlengiswa ngokwemvakalelo yobushushu.

Iyunithi yokuthuthwa kwempahla

Umbungu othathu kumatshini wokutsala uqinisekisa ukuba umbhobho oveliswayo usebenza ngokuzinzileyo kwaye uzinzile. Sisebenzisa indlela ekhethekileyo yokuthintela umbhobho ovality ngelixa idizayini yethu ekhethekileyo yebhanti iqinisekisa ukutsalwa ngokufanelekileyo ngaphandle kokutyibilika. Umatshini wethu wokutsalwa kwemibhobho ziimoto ze-servo eziqhutywa ukuba zinyuke

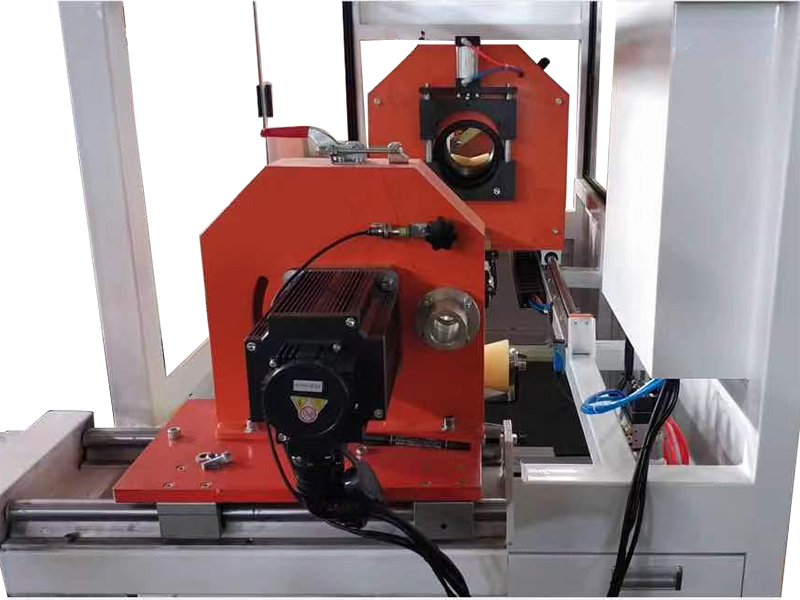

Umsiki okhawulezayo

Sinikezela nge-cutter ngokukhawuleza kumgca wokuvelisa we-PP-R njengoko isantya sokukhupha kumbhobho sikhawuleza. Umgca wokuvelisa we-PP-R unenkqubo yokulawula ye-PLC ehlakaniphile. Inokunqunyulwa kubude obuchanekileyo ukufumana imveliso yedimension esisigxina.